35 years ago Gambler set out to make one of the most advanced high-performance bass boat the market had ever seen. At a time when most bass boats looked more like fiberglass bathtubs, Gambler’s combination of sleek lines, racing hull heritage, and full tournament fishing functionality was an immediate success. Innovation is what created the very first Gambler Bass Boat, so pushing the envelope is simply in our DNA. Year after year we have continued to raise the bar with unique and revolutionary innovation. From the first raised flipping decks in the mid 80’s to the patented “Hydrolock Hull Design” and HPI foam core liner hulls of the 2000s; the list of industry firsts and Gambler exclusives is astounding. Below is a short list of just a few of the technical design aspects that separate Gambler Bass Boats from all the other cookie-cutter, mass-produced boats currently on the market.

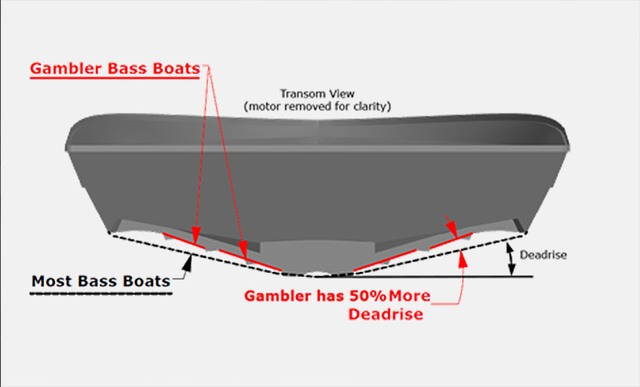

Our uniquely shaped and contoured high lift pad provides enormous load carrying capacity, fuel economy, and blistering top-end speed.

The concave tunnel along the length of the pad entraps the highly aerated water from the forward projected whisker spray that's typically displaced outward by flat or v-shaped pads. This aerated mixture down the entire length of the wetted pad reduces drag, and allowing us to run a wider pad with increased load carrying capacity without sacrificing an appreciable amount of speed. The pad is also carefully contoured fore to aft to perfectly align the most hydrodynamically efficient angle of attack for the pad, with the ideal aerodynamic angle of attack for the rest of the hull.

The results are amazing. Top speeds typically only vary by 1 to 2 mph whether fully loaded, completely empty, one person vs two, etc.; and with the current generation of 250 hp 4-stroke outboards the fuel economy readings remain right at 3.5 mpg even at speeds over 80 mph. If you’ve been around boats for any length of time you will immediately appreciate what a marvel of engineering this truly is.

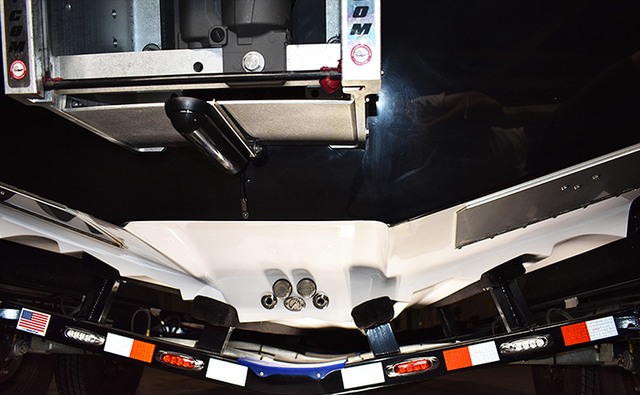

Gamblers hulls have a much larger transom offset than you may be accustom to. This began with countless hours refinement, and shaving fractions of an inch at time in order to find the optimum pad location for the most stable balance point over a broad range of load conditions. We then began removing every inch of the speed robbing hull surface that wasn’t 100% necessary for optimum performance. Even though we had taken it much farther than most bass boat builders at that point we didn't stop there. We then started carving away at the areas that caught the most spray until we ended up with the very unique design pictured here.

Removing the excess wetted surface area aft of the dynamic center of gravity, and contouring the step to allow the spray to separate cleanly from hull resulted in big gains in efficiency, and top end speed.

Massive 20” electric trim tabs are built into each side of the optimized transom step. The trim tabs were initially intended to compensate for the large transom offset, and its impact on hole-shot; however, they quickly proved to have other very valuable functions while bass fishing. The tremendous amount of lift generated at the stern keeps the boat practically flat when getting on and off of plane, and allows the boat to take off and sit down in water 1 to 2 feet shallower than any other bass boat without risking damage to your prop or lower unit.

With the trim tabs, the boat is also able to stay on plane at extremely low speeds - as low as 10 mph depending on your setup - making these boats both some of the fastest, and slowest available on the market. Being able to maintain this low planning speed has proven tremendously valuable for graphing new areas during practice. You can quickly graph large areas and locate key contour breaks, primary structure features, large schools of bait, etc. without ever having to stop and idle around.

Probably the most frequently praised benefits of the tabs from our customers is the ability to stabilize and control the boat in rough water. The pitch control lets you run flat through large waves that would otherwise launch any 20 or 21-foot boat, and in extreme conditions the ultra-low speed planning ability lets you to continue on plane safely when your competitors all have to back down and idle.

Gambler’s unique hull design incorporates varying surface geometry that is continuously divergent to natural wave surface geometry. More simply, each section of the hull is shaped to avoid alignment with the face angle of oncoming waves. Why do we care about the angle between the hull and the face of waves? Imagine slapping a paddle on the water with its broad face aligned and flat to the water’s surface. Now imagine doing it again and again with the paddle at increasing (diverging) angles to the water surface. Most can readily predict that the impact force goes down as the angle goes up. The exact same physics applies to boat hulls and ride quality. By carefully shaping the hull to avoid the typical angles of on-coming waves the hull simply never really catches anything squarely "on the chin" so to speak. Combine this with the shear mass of the hull's bullet-proof heavy-weight layup, and you get the smoothest "big boat" ride available today, and 80+ mph top speeds.

Skeptical? Good. You should be. With all the hollow claims from other manufacturers flying around these days it's to be expected. Schedule a demo ride today and come see for yourself. We'll stand by every claim we make, and back them up - on camera.

The new Gambler hulls have an extended reversed chine that runs from the stern all the way to the nose of the boat. The chine on previous Gambler hulls (e.g. 206, 209, 2100, & 2200) all tapered sharply up towards the rub rail just past mid-ship. This made the nose of the boat sleek and flat, but removed critical surface area needed to provide lift to the bow when landing into the face of a big wave. As a result they were known to “stuff” a wave or two from time to time.

This has been completely addressed with new extended chines. The new chines have massive tunnels that dramatically increase both aerodynamic and hydrodynamic lift at the bow, and also do a better job redirecting spray down and away from the hull. The result is a significantly dryer ride overall.

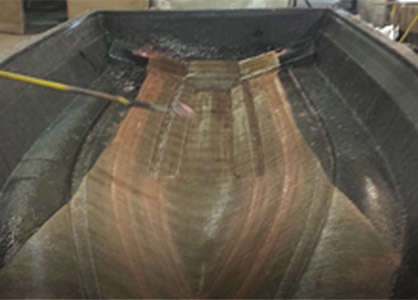

The 100% all composite hull is hand laminated using fine finish exterior fiber glass mat, high strength structural bi-axial fiberglass fabric, composite sandwich-core materials, and a layer of Kevlar that runs the entire length of the hull, providing extreme puncture resistance and strength.

The hull is structurally reinforced with hand laminated full-length composite stringers and keel. The high-density composite transom is reinforced with hand laminated composite knee braces that have been engineered and oriented for maximum rigidity. The result is a brawny, 1-piece, 100% composite structure that will handle the whatever you can dish-out with ease.

Gambler Boats are one of the only manufacturers left on the planet that still utilizes the more costly, but structurally superior double hull construction. This double hull construction incorporates a complete full length inner hull (liner) into the already stout primary hull. The entire hull/liner assembly process takes place while both components are still fully seated in their molds. The liner mold is flipped over and placed into the hull mold where it is chemically bonded with epoxy around the entire perimeter of the hull, as well as in several other strategic locations creating a singular watertight structure. The two molds are then bolted together locking everything in place, and high pressure structural, closed cell flotation foam is injected through a series of ports completely filling the space between the liner and the hull throughout the entire length of the boat. The result is a literally unsinkable boat, with a unrivaled solid feel that can only be achieved with this type of construction.

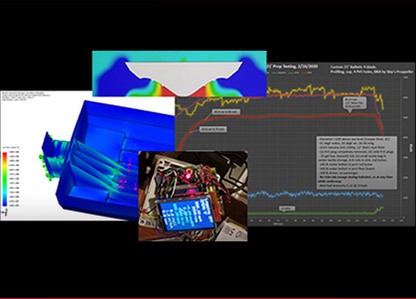

From custom electronics for precision R&D testing, to advanced Finite Element Analysis (FEA) and Computational Fluid Dynamics modeling; we have the engineering expertise and knowledge to design and build boats that you can depend on to perform year after year. Every aspect of a these boats is designed for the absolute worst case typical use scenario, and then a factor of safety of x2 is often added on top of that. These boats have been meticulously engineered to handle whatever you can throw at them, so that the only thing you have worry about when you’re on the water is catching fish.

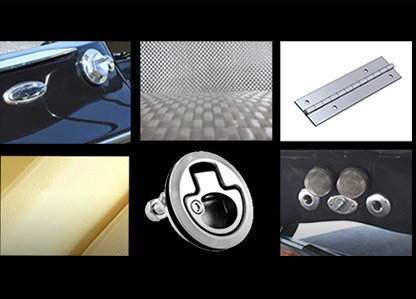

All it takes is one switch, one pump, or one loose wire to cost you a big payday, a podium finish, or worse. That’s simply not a risk we’re willing to take. From the stainless steel latches and hardware, crisp all LED lighting, marine grade plug-in wiring harness - to the vinylester barrier coating for most durable long lasting gelcoat finishes possible. You can rest assured that whatever we put on your boat is the absolute best part, component, or material that we could find.

Every boat gets fully water tested before it leaves the factory. We check every switch, light, latch, and pump; and operate EVERY feature on the boat to insure that everything is 100% ready to go. Then we haul it back to the shop and run through everything in one last final check to insure that every fastener is snug, every component is securely in place, and every square inch is flawless. We pride ourselves on the quality of our work and our manufacturing process, but it would be a lie to say that we never caught any issues during or after water testing. However, that's precisely why we do them, and why you won’t have to.

We’re so confident in the quality of the engineering, craftsmanship, and materials that go into making your new boat that we’ll stand behind it for as long as you own the boat. Give us a call or send us an email to request a copy of our warranty policy, or learn more about our unrivaled Commitment to Excellence.